Back to top

The best place to but the latest Semi Automatic Mild Steel Wind Tunnels, Hydrostatic Pressure Apparatuses, and many other products.

HOT PRODUCTS

Incepted in the year 2008, we, Mechmatics Engineering Pvt. Ltd., are a leading company from Ahmedabad, Gujarat. We are a manufacturer, supplier, and service provider dedicated to elevating our success levels by offering a wide assortment of industrial machinery, electronics & electrical supplies, and testing & measuring equipment. Our product range includes 2 Inch Stainless Steel Hydraulic Ball Valves, Low Energy Mild Steel Electrical CNC Machines, Fluid Mechanics Laboratory, Hydrostatic Pressure Apparatuses, Semi Automatic Mild Steel Wind Tunnel, etc. These products are delivered timely and safely at client locations with the help of a pan-India dealer network and distributors.

The founders of Mechmatics Engineering Pvt. Ltd. are experienced engineers who have practical knowledge of the industry. Under their guidance, the company is progressing with the mission of being a part of every research that can benefit mankind. The founders are visionary which becomes clear with the establishment of state of the art in-house facilities for design, production, and training that are future-oriented.

Our Infrastructure

We have a modern and well-designed infrastructure in Ahmedabad, Gujarat, India. Here, we have different facilities and units that enable us to have a large production rate of quality assured products. In our infrastructure, we have two production units that feature the latest machines having less downtime.

Why Choose Us?

We are a leading company offering Semi Automatic Mild Steel Wind Tunnel, Low Energy Mild Steel Electrical CNC Machines, Hydrostatic Pressure Apparatus, Fluid Mechanics Laboratory, 2 Inch Stainless Steel Hydraulic Ball Valves, and other products. The quality and performance of these products have made us a leading choice of the customers. They also prefer to deal with us because of our ability to complete large orders and quotation of competitive prices.

Customized Services For Researchers

- Design: At Mechmatics Engineering Pvt. Ltd., we design simple mechanisms to complex assemblies according to the needs of customers. We refine the imagination of the customers into a virtual model. Herein, we receive input from the clients in different forms like handwritten, verbal descriptions, flowcharts, and even a standard CAD layout. After this, the input is fine-tuned by our professional into a design that can be manufactured. The entire process is done in-house and every iteration mentioned in the blueprint is done after consulting the end-users.

- Fabricate: We fabricate all types of products such as fixtures, frameworks, machining components, and panels in different materials such as glass, plastic, wood, and metals like steel, perspex, and non-ferrous. To date, we have completed all types of projects from 100-ton structural frames to micro-mini flow channels. For the fabrication process, we have an in-house machining facility having routers, lathe machines, and a separate welding department. We conduct measurement checks as a part of our quality inspections to make sure that products are made in the closest tolerances.

- Automate: The integration of mechanical and electronic systems ensures complete peace of mind. The data acquisition system we use is proprietary and we work with many vendor materials. The data acquired system allows us to work with various sensors like pressure, distance, color, flow, light, temperature, velocity, force, vibration, and many others. In all our rigs, there are various electrical components & instrumentation & control systems. Through automation solutions, we meet the requirements of pneumatic, hydraulic, and servo-controlled systems.

- Research: Since our inception, we have been completing customized testing setups for reputed institutes in India. In fact, we have the longest experimental setup in Western India.

The Latest Projects of Mechmatics Engineering Pvt. Ltd.

Check out our entire product portfolio of Low Energy Mild Steel Electrical CNC Machines, Fluid Mechanics Laboratory, 2 Inch Stainless Steel Hydraulic Ball Valves, and others made according to your requirements. From the time of our establishment, we have successfully acquired a 100% perfection rate in every project executed by us. A brief of our latest projects is given below:

- Understanding Radiation Impact Through Automatic Air Moisture Sample Collector: In all the Nuclear Power Plants, the most important radionuclide element is Tritium, which is regularly monitored. The presence of Tritium in air is calculated via air moisture collection and assessment via Liquid Scintillation Analyser. The use of this indigenous technology enables the automatic collection of air moisture via the thermo-electric cooling principle of the Peltier effect. We have installed such machinery in India at all the NPCIL sites via a technology transfer agreement with Bhabha Atomic Research Centre.

- The 3-In-1 Water Conservation Device: The Solar Water Team is dedicatedly working to designing a portable device that will use sun energy for the purpose of creating water from air moisture along with fulfilling the purpose of a sewage treatment and desalination unit. The prototype of this device is already developed and has all the required sensors and controllers for collecting the data.

- Enhancing The Performance of Heat Sinks: Our manufacturing support is extended to the investigators who are known for patenting their designs. We provide Double-layered Micro-channel Heat Sinks, a new product, whose geometry ensures the improvement of the cooling efficiency of all the microelectronic mechanical systems. For the verification of the tolerance, our manufactured product is passed through stringent examination under the lens of the electron microscope.

- Long Channel; Multi Pipe Two-Phase Flow Setup: We have set up examinations on the intermittent type two-phase gas-liquid flow via pipes which is present in applications such as atomic power plants, geothermal energy systems, desalination plants, crude oil industry, and chemical process plants. Material degradation and wall thinning are two of the common issues in long-distance pipelines, especially those that carry 2 phases like oil and natural gas or air-water mixture in the form of steam. It is because of erosion or corrosion that occurs in the piping systems. The two-phase flow setup comprises:

- 20 mtrs length with three different pipe diameters

- High-speed flow visualization camera

- Hot-film anemometry system with automated traverse

- Laser Doppler Velocimetry (LDV)

- Pressure measurement system including high response pressure transducers

- SCADA system

- Water and air flow loop

- Pool Boiling Investigations On Refrigerants: Applications like refrigeration, power generation, refining, and others demand the processes of boiling and condensation for transferring heat from a hotter to a colder region. Here, convective, nucleate, and film boiling occur, whose understanding is important to ensure improved design, operation, or service. For this purpose, we have built a rig that is customized with complete instrumentation for monitoring flow, temperature, pressure, and power. The rig has a visualization section for efficacious linkage amid theoretical and practical aspects of critical flux.

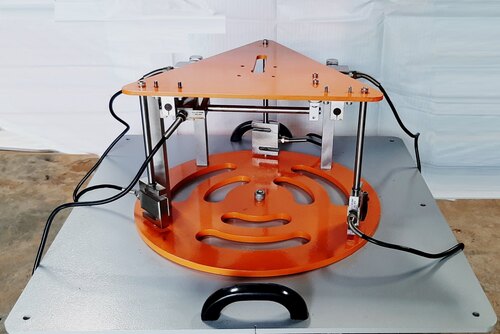

- MOU For Sharing Wind Testing Facility: There are several applications of the wind tunnel. The basic application is as a wind generation source on the laboratory scale. In the tunnel, there is a test section in the middle, which creates a scale-down environment for mimicking real-world wind conditions. Here are a few of its applications:

- Wind load tests on all the building models

- Drag Forces that act on surfaces like high mast poles

- Flow visualizations in all the automobiles

- Betterment of the aerodynamics in sports like cycling

Our manufactured Wind Tunnel Facility is installed at Silveroak University. With this university, we have signed a MOU according to which the facility may be used to conduct external industrial testing during the non-teaching time. It is the best example of the perfect Industry-Academic Partnership.

Send Inquiry

Send Inquiry Send SMS

Send SMS